People in the chemical industry started looking for better stabilizers decades ago, once they saw problems with early formulations for plastics and rubbers. They wanted additives that offered more than just simple thermal support—solutions that could give a higher degree of color retention and long-term reliability under stress. Synthesizing organophosphites took off in the mid-20th century, with phenyl diisodecyl phosphite eventually making its mark as a trusted compound. Its unique structure struck a balance between chemical stability and processability. Manufacturers kept pushing boundaries, so the search for better performance never really ended, and phenyl diisodecyl phosphite benefited from the steady march of synthetic and purification technology.

Phenyl diisodecyl phosphite lives in the world of plasticizers and stabilizers. Unlike old-school metal-based stabilizers that struggle with environmental regulations, this compound represents a cleaner and more consistent option. It serves as a secondary stabilizer, often working with primary stabilizers like organotin or calcium-zinc systems. The combination helps plastic products resist yellowing, brittleness, and loss of flexibility. This material actually shows up as a pale liquid or light yellow oily substance, which means it blends well and flows easily in manufacturing plants. Its key selling point stems from its chemical compatibility and low volatility compared to legacy phosphites.

Phenyl diisodecyl phosphite stands out because of its specific gravity in the range of 0.93–0.97 at room temperature. Its viscosity usually hits mid-range, making pumping and mixing straightforward without clogging equipment. The material doesn’t give off a strong smell, which helps cut down on worker discomfort. This noncrystalline form ensures cleaner handling. It dissolves well in a wide range of organic solvents, which means it can be used in flexible vinyls, polyolefins, and a bunch of specialty coatings. Its thermal decomposition point sits well above typical processing temps for plastics, making it less likely to break down during compounding or extrusion. This durability allows for long-lasting antioxidant effects in the final polymer.

Labels list phenyl diisodecyl phosphite’s minimum assay (usually above 95%), acidity in terms of mg KOH/g, and water content, which matters a lot for shelf stability. Manufacturers often point out the absence of heavy metals, because regulators keep a close eye on additives that might escape into the environment or leach from finished goods. Packaging includes hazard and precautionary statements laid out by GHS (Globally Harmonized System), since improper handling can cause eye or skin irritation. Standard drum sizes keep things easy for logistics—the 200L steel drum feels almost like a global standard for these types of chemicals.

Heading into the lab, chemists usually react phenol with isodecyl alcohol in the presence of phosphorus trichloride under controlled conditions. The reaction runs under an inert gas to keep out oxygen and moisture, which could trigger side reactions. Once the main phosphite compound forms, the crude mix moves through neutralization, washing, and filtration. Removing unreacted starting materials and trace acids requires careful monitoring. The liquid gets dried using vacuum distillation so water content stays low, a step that has saved many a batch from premature spoilage. Careful operators have learned that skipping post-reaction purification can introduce impurities that hurt performance in plastics.

Phenyl diisodecyl phosphite isn’t entirely static—it can form adducts or react with certain acids thanks to its free phenyl group. It gets involved in transesterification reactions when blended in flexible PVC or polyolefin recipes. In oxidative conditions, it acts as a scavenger, trapping hydrogen chloride and other degrading agents before they can attack the polymer backbone. This role sits at the core of its reputation as a stabilizer. In some labs, researchers tweak its molecular structure, swapping isodecyl chains for similar alcohols, to tailor the balance between melt stability and volatility. This room for fine-tuning brings a certain level of customization to plastics compounding.

Customers might come across a handful of synonyms while sourcing this compound. Names like “DIDPP” or “phenyl diisodecyl phosphite” show up frequently. Catalogs also list trade names reflecting proprietary syntheses or slight modifications. Some suppliers use regional labeling conventions, causing confusion for newcomers, so checking chemical abstracts or standardized codes usually clears things up. This variety in naming can lead to mix-ups unless a buyer drills down into the full molecular structure.

The modern plant floor uses strict protocols around phenyl diisodecyl phosphite. Even if the liquid doesn’t attack steel or most plastics, surface spills need cleanup since slipperiness poses a risk. Standards from OSHA and REACH drive training for personnel, making sure goggles and gloves stay part of the uniform. Good ventilation limits inhalation, and SDS (Safety Data Sheets) get reviewed before handling. Regulatory agencies often look for clear records of exposure limits and periodic air monitoring. Transport falls under international dangerous goods requirements, especially since higher temperatures boost the risk of vapors.

Industrial users reach for phenyl diisodecyl phosphite when making PVC films, flexible hoses, plasticized floor coverings, and automotive interior trims. It shows real flexibility in cable insulation, where thermal stability pairs with a need to avoid breakdown during electrical surges. Print shops and ink makers keep it as part of their formulations to support color fastness. The food packaging sector sometimes taps it, provided migration research confirms no transfer into food. I remember examining a PVC appliance cord that held up well to six months of accelerated aging—evidence that stabilizer choice has a real overnight impact on durability.

Academic labs keep publishing new findings around organophosphite stabilizers. Ongoing work explores replacements for ingredients that regulators flagged as endocrine disruptors or persistent organic pollutants. Studies published in polymer science journals compare various side chain modifications to see which bring down cost while lifting performance. Some teams look at blending phenyl diisodecyl phosphite with UV stabilizers for outdoor plastics, since harsh sunlight breaks down many polymers quickly. The race toward “greener” chemistry puts pressure on ingredient suppliers to document life-cycle impact, so R&D now pays more attention to raw material sourcing and byproduct elimination during synthesis. The competition to balance price, safety, and technical edge keeps this area on the move.

Lab animals exposed to phenyl diisodecyl phosphite at relevant doses don’t show acute toxicity, but chronic effects become a real point of concern for regulators. Testing includes skin and eye irritation, potential for respiratory problems, and reproductive outcomes. Environmental fate testing looks at biodegradability and accumulation in aquatic systems. Water authorities ask tough questions since chemicals with high persistence hang around and impact fish or drinking water supplies. Routine screening for metabolites ensures that nothing dangerous slips through the cracks when plastic products degrade. Keeping toxicity in check often means stricter purity levels, better worker training, and transparent reporting of results to the authorities and downstream customers.

Legislation in Europe and North America keeps raising the bar for safety and sustainability, affecting both ingredients and end-use products. Customers expect lower toxicity, easier waste handling, and a lighter environmental footprint. The market could shift as new stabilizers emerge, but phenyl diisodecyl phosphite still plays a role for demanding plastic and rubber formulations. Research into renewable feedstocks—using bio-based alcohols or greener phenols—could reshape its manufacturing. Digital process control and continuous-flow synthesis cut down on waste and energy, so future plants won’t look much like today’s. Every improvement in safety, efficiency, or performance, though, depends on honest reporting, independent oversight, and a willingness to test new approaches before adopting them. If innovators keep listening to real-world feedback from production floors and recyclers, tomorrow’s additives stand a better chance of earning trust and market share.

Walk through any supermarket and you’re surrounded by plastics. Modern packaging, electrical cords, car interiors—products rely on certain chemicals to stay tough and safe under stress. Phenyl Diisodecyl Phosphite pops up here, playing a key role in making plastics durable and protecting them from falling apart. Its job involves slowing down how quickly plastic materials break down in the sun, heat, or over time. Factories can’t easily swap it out. Its impact doesn’t usually get noticed by the public, but the people designing plastics count on this additive to keep their products performing as promised.

Plastics absorb energy from sunlight and heat—think about a plastic chair fading or turning brittle after a summer outside. What happens inside? The molecules break apart. Phenyl Diisodecyl Phosphite steps in to catch those damaging free radicals, slowing down the process known as oxidation. Chemists call it an antioxidant, but it acts like a shield, catching the troublemakers before they do harm. Even a small mistake with stabilizers means your garden hose cracks after one season, or your appliance cords get sticky and weak.

It’s easy to shrug off chemical names that sound complicated, but quality and safety often hinge on these details. Take electrical cables. Wires must handle plenty of current and heat. If their insulation degrades, they turn into a risk—sparks, short circuits, or fires follow. Adding compounds like Phenyl Diisodecyl Phosphite helps insulation resist heat and last far longer. In car interiors, seats and dashboards face sunlight pouring through windows. Using stabilizers protects these surfaces from chalking, discoloration, and cracks, so they last as long as the engine.

No chemical sits above scrutiny. Every time we use an additive, there’s a chance it could end up somewhere it shouldn’t—landfills, rivers, even the air. Some phosphite-based stabilizers have drawn attention on this front. Regulatory agencies keep a close watch, evaluating new studies on how much escapes products and how it moves through the environment. Industry standards require thorough testing, often guided by third-party labs and independent audits.

There’s a tension in using chemical additives—to keep things lasting longer, but not create bigger environmental headaches. Some companies keep searching for alternatives. Phosphite stabilizers like this one still get plenty of support with established safety records when used as directed. Better recycling, responsible disposal of plastics, and using as little as needed make a difference. Many researchers try to develop stabilizers from safer raw materials or natural sources. Progress tends to build step by step—improving how much we understand both the benefits and side effects, and how to keep useful technology from creating hidden costs for health and the environment.

I've seen chemical names that sound like a mouthful, but Phenyl Diisodecyl Phosphite (often abbreviated to PDIDP) tops the list for some. This stuff gets plenty of use as a stabilizer in plastics and rubber, mostly to help materials last longer and take the heat. Some folks working around PVC and synthetic rubber run into it a lot. On one hand, these stabilizers keep products solid and usable. On the other, not everyone spends much time wondering if something that keeps plastic strong causes trouble for people handling it.

Toxicological data tells us PDIDP didn’t show eye irritation in rabbits, and no bad skin reactions during short-term studies on lab animals. The European Food Safety Authority and EPA both looked into its risks. In labs, PDIDP breaks down slowly, tends to stick around in the environment, and can build up in living tissue. That can raise real concerns, especially for workers spending years in environments with repeated exposure.

The American Conference of Governmental Industrial Hygienists notes that just because a substance doesn’t cause an immediate rash or cough doesn’t mean it’s completely harmless. With PDIDP, dust or mist can irritate lungs or eyes during high-exposure events. Most health effects won’t jump out after a single shift in the warehouse, but chronic exposure is another story.

Personal experience in production plants taught me one thing: the strongest safety culture is built on steady habits. Workers wearing gloves and goggles catch odd looks at first, but nobody laughs after the first chemical splash sends someone to the nurse. Even though PDIDP isn’t the most notorious chemical, I noticed that places that used it without ventilation dealt with more coughing and eye complaints. Strong air handling wasn’t just for comfort—people felt better, worker turnover dropped, and mistakes shrank.

I remember a site that skipped regular safety audits for six months. Bottles with faded labels sat next to dusty fans pushing vapor into walkways. Later, records showed higher absenteeism and sick days in that stretch. Once management invested in clear labeling, spill kits, and mask stations, the problems shrank. Over time, no one wanted to go back to the “old days.” Operators became the most vocal safety advocates, rather than supervisors always scolding from afar.

Chemical protective equipment—or “PPE”—isn’t the only answer, but it buys time and confidence. Clean gloves, fitted goggles, and approved respirators stop most issues before they start. Following guidelines called for by the Safety Data Sheets makes a difference. Good ventilation and routine maintenance on the extraction units turn what used to be a risky guessing game into a reliable process.

Getting every worker on board takes more than a poster on a wall. Ongoing training, updates when new studies come out, and open discussion during toolbox talks make chemicals less mysterious. It means nobody shares leftover food near the tanks or skips their mask because “last time was fine.”

Workplaces must keep track of air quality, enforce safe storage, and make emergency wash stations easy to reach. Management support, real budgets for upgrades, and respect for the ones “on the ground” close the loop. You build trust, not just safety, by listening. Chemical safety isn’t about avoiding headlines—it’s about giving people dignity, control, and the peace of mind to do the job right.

The name itself doesn’t roll off the tongue, but Phenyl Diisodecyl Phosphite has a role in a range of polymer and plastic manufacturing processes, often as a stabilizer. Anyone handling this compound will instantly notice its strong odor and an oily consistency. I’ve worked with phosphites in a small materials lab, and I’ve learned that casual handling can invite headaches, sometimes literally. Poor storage can ruin whole batches and cause health or environmental issues that nobody wants to face.

Common sense beats complicated jargon. This compound fares best in a cool, dry place. It reacts with moisture over time. I remember keeping it in a dedicated metal cabinet after someone once stored a similar phosphite too close to a leaky sink. Bad news followed: fumes in the storeroom, ruined stock, expense. You want your workspace free of leaks or sudden temperature swings — heat speeds up degradation, while any water in the air slowly turns the stuff acidic.

UV light is another troublemaker. Direct sunlight strips away the compound’s effectiveness day by day. Shaded, closed cupboards with little exposure to outside air and no bright light will do much better. A sealed, chemical-resistant container prevents oxygen and water vapor from sneaking in. Many forget to double-check the seals or use the original packaging, but swapping out containers can open the door to slow contamination.

In my experience, neat storage areas cut down on emergency calls and lost product. Phenyl Diisodecyl Phosphite will irritate your skin and eyes, so I always wear gloves and goggles and keep spills from spreading. I trust secondary containment trays — a simple, cheap fix — to catch any drips. No one should store food or drinks anywhere nearby, since even a trace left on your hands can irritate skin or cause problems if ingested by accident.

Label everything clearly. Unmarked bottles are a recipe for disaster and lead to accidental mixing. I once saw a co-worker pour waste into an unlabeled jug, forcing a whole room evacuation because nobody knew what was in it. Proper labeling and keeping an inventory list avoids confusion and saves hours of frantic searching.

If the container develops a leak, move it to a ventilated spot and clean up using absorbent material suitable for oily, chemical spills — not ordinary paper towels. Wet chemistry students often forget to check expiry dates, but the product loses stability over months and degrades faster in bad conditions. Disposal follows local hazardous waste rules; pouring it down the drain or in the trash brings trouble with environmental regulators.

Manufacturers might supply updated guidance for modern packaging and handling, but the basics remain the same: keep the material sealed, cool, out of the light, and away from moisture. Training new staff through hands-on demos, not just paperwork, leads to safer habits and fewer accidents. Every worker, from a fresh hire to the most senior tech, benefits from clear, visible reminders and practical checks. Staying alert means fewer headaches — both from chemical odors and lost profits.

Chemicals drive so much of modern living, even in places most folks would never suspect. Phenyl diisodecyl phosphite, with the chemical formula C33H51O3P, might sound like a string of alphabet soup, but it plays a bigger role in industry than people recognize. Getting the formula right is not a chemistry class exercise—it’s a window into responsible manufacturing and safe product handling. Each letter and number maps to a real atom inside the molecule, and the combination tells professionals how the chemical behaves when exposed to heat, light, or other substances.

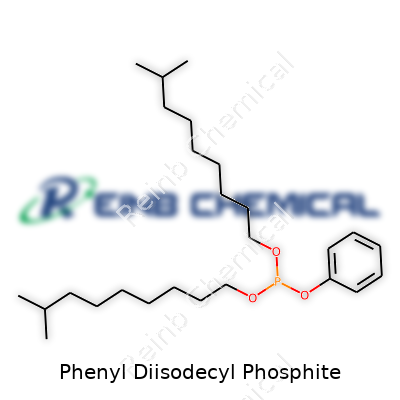

Look at the formula closely: thirty-three carbons, fifty-one hydrogens, three oxygens, and a single phosphorus atom. This compound combines a phenyl (aromatic ring) group with two isodecyl chains attached through phosphite. Those big, branching isodecyl groups give it bulk and flexibility, making it incredibly useful as a stabilizer in plastics, especially in polyvinyl chloride (PVC) production. The phenyl part adds antioxidant properties. That mix means products stay clearer for longer and last through sunlight and heat, which helps both factories and end-users.

In my years of following industrial safety stories, getting that formula wrong isn’t just a paperwork slip. Companies firing up a process without understanding the molecular makeup can slightly change temperature or mixing details and set off a costly mistake—or even an accident. Each element’s position sets off chain reactions with dozens of other ingredients on the factory floor. Engineers, safety officers, and regulators depend on the accuracy of formulas to set limits: how much pressure a tank can handle, what kind of fire suppression system makes sense, and the right gear for workers. Good information means fewer surprises, less downtime, and better health outcomes.

Safety and environmental impacts matter. Phosphite stabilizers like phenyl diisodecyl phosphite don’t last forever. They age, break down, and sometimes leave behind byproducts that slip into soil or water. The chemical formula forms the basis for assessing these impacts. Regulatory agencies use it to develop guidelines on disposal and emissions. I’ve seen teams working to improve containment and recycling because stricter rules and community expectations run strong.

People ask: “Why can’t we swap it with something greener?” Replacements haven’t always lived up to the stability or lifespan of phosphite-based stabilizers. Real progress happens when chemists publish research on tweaks to the original structure—adding groups to make breakdown products safer, or changing how these phosphites bond with other substances. Industry partnerships and academic labs keep pushing the boundaries, partially because knowing the formula lets researchers model and test thousands of small changes safely before using them in real life.

Honest disclosure of chemical formulas like C33H51O3P helps keep the public, regulators, and industries connected. Advances in chemical safety grow from this foundation—clear formulas, strong facts, and ongoing evaluation. My experience tells me that the free flow of technical details does not only drive smart regulation but also helps communities feel informed when new manufacturing plants pop up down the street. Knowledge, shared openly, forms the groundwork for improvement and trust.

A lot of folks outside of the plastics or chemicals industry might skip right over the term Phenyl Diisodecyl Phosphite, but this compound regularly finds its way into a range of industrial applications, especially as a stabilizer for PVC. Truth is, debates about additives like this run deeper than any chemistry class or data sheet lets on. The world doesn’t always get the full picture from technical lingo, so let’s break it down.

Reading lab reports, you notice that Phenyl Diisodecyl Phosphite isn’t famous for being a household toxin, yet small details matter. The stuff doesn’t just vanish after a batch of plastic gets molded. Take runoff as an example. Wastewater from plants can pick up trace amounts. Over time, phosphite-based stabilizers have a habit of finding their way into rivers and streams. Here’s what nags at me: phosphites often oxidize to phosphates, and those phosphates fuel algae blooms. Walk by a lake covered in green foam, and you can see how a simple compound can twist the balance for every critter living there.

This isn’t some wild scenario. Studies in European wastewater found higher concentrations of organophosphites near plastics manufacturing zones compared to upstream sites. Regulatory bodies admit the breakdown products—especially certain phenols—stick around, potentially causing trouble for aquatic life.

On the human side, it’s less about touching a product and more about what sifts through the water and food chain. The pieces rarely cause serious issues right away. But if phenolic breakdown products escape into fish or crops, you trade slow, low-level exposure for big open questions. For wildlife, it’s a double whammy: fish and frogs don’t only lose oxygen to algae blooms, they also face the residue left over in the mud and silt. In my view, short-term studies often miss these long-range glitches, since nature’s feedback loop rarely files its complaints on a corporate quarterly report schedule.

In factories, I’ve watched operators handle this chemical with gloves and goggles. Inside those walls, hazard gets recognized openly. On the outside, the chemical drifts with each washdown or spill. Regulatory guidelines acknowledge possible chronic effects, but enforcement gaps mean standards vary. Isn’t it noteworthy how easy it is for compounds to slip through the cracks between legal compliance and actual environmental health?

Instead of letting cleanup chase after accidental leaks, preventive steps matter. Treatment systems can strip out organophosphite residues before wastewater leaves a plant. Sensors help track concentrations in real time, not a month after the fact. It also pays to invest in greener alternatives—non-phosphorus-based stabilizers are cropping up that skip some of these hazards entirely. Public databases make chemical releases more transparent, and that pushes manufacturers to up their game.

Down the line, awareness plays its part. Following the trail from plant to riverbank means the story stays honest—not buried behind technical phrases. To deal with any environmental risk, it takes steady watchfulness, the right technology, and the patience to admit that no short-term profit fixes a long-term mess.

| Names | |

| Preferred IUPAC name | tris(8-methylnonyl) phenyl phosphite |

| Other names |

Phosphorous Acid, Diisodecyl Phenyl Ester Diisodecyl Phenyl Phosphite Phenyl Disodecyl Phosphite Diisodecylphenyl Phosphite |

| Pronunciation | /ˈfiːnaɪl daɪˌaɪsoʊˈdɛsɪl ˈfɒsfaɪt/ |

| Identifiers | |

| CAS Number | 25550-98-5 |

| Beilstein Reference | 2843703 |

| ChEBI | CHEBI:91849 |

| ChEMBL | CHEMBL1891877 |

| ChemSpider | 14169906 |

| DrugBank | DB11259 |

| ECHA InfoCard | ECHA InfoCard: 100.099.782 |

| EC Number | 238-714-2 |

| Gmelin Reference | 613370 |

| KEGG | C22106 |

| MeSH | D010667 |

| PubChem CID | 91696 |

| RTECS number | SZ8400000 |

| UNII | K33B58Q936 |

| UN number | UN2310 |

| Properties | |

| Chemical formula | C28H51O3P |

| Molar mass | 586.8 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 0.97 g/cm3 |

| Solubility in water | Insoluble |

| log P | 8.8 |

| Vapor pressure | <0.0001 mmHg (20°C) |

| Acidity (pKa) | 1.82 |

| Basicity (pKb) | 15.6 |

| Magnetic susceptibility (χ) | -83.73e-6 cm³/mol |

| Refractive index (nD) | 1.491 |

| Viscosity | 760.0 cP (25°C) |

| Dipole moment | 2.22 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 1014.7 J·mol⁻¹·K⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H315, H319, H411 |

| Precautionary statements | P210, P273, P280, P301+P312, P305+P351+P338, P501 |

| NFPA 704 (fire diamond) | 1-1-0-健康危害-特殊なし |

| Flash point | Flash point: 204°C (399.2°F) (Closed cup) |

| Autoignition temperature | 270°C |

| Lethal dose or concentration | LD50 (Oral, Rat): > 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral > 15,800 mg/kg |

| NIOSH | TC9295000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.2 mg/m3 |

| Related compounds | |

| Related compounds |

Triphenyl phosphite Tris(2-ethylhexyl) phosphite Triisodecyl phosphite |