Chemists chasing efficient ways to produce phenolic resins and antioxidants have explored the value of p-Diisopropylbenzene for decades. Early interest sprang up in the post-war era, as the chemical industry expanded efforts to replace natural products with synthetic solutions. Industrial history often overlooks this compound, but its roots tie into the aromatic hydrocarbon renaissance, especially as petroleum refining created more robust streams of benzene and propylene. A generation later, big plants in Europe and East Asia refined continuous alkylation, giving rise to reliable p-Diisopropylbenzene output. Academic research, especially in the 1960s, chipped in with catalytic studies that set today's scale. Honest progress, in both benchtop and pilot plant, turned a curious side product into a staple for specialty chemicals.

Today, p-Diisopropylbenzene fills a narrow but important niche. Demand may not compare with bulk aromatics, yet the users span from fine chemical synthesis to the forming of specialty plastics. Its value shows up in intermediate steps: those chasing antioxidant materials or aiming for rigid phenolic polymers learn its strengths. Bulk buyers tend to value purity, knowing that even minor contaminants can trip up high-stakes chemical reactions. As with anything built from benzene, a sharp eye on product stewardship defines how each drum moves from manufacturer to plant. Years of technical feedback and performance data filter down to the buyers who know their application hinges on batch consistency more than almost any headline property.

p-Diisopropylbenzene posts a boiling point around 236°C and a melting point hovering near -23°C, offering a liquid state across a wide industrial temperature band. It comes as a colorless liquid, with a faint aromatic scent that’s a hallmark of its benzene backbone. The compound weighs in with a molecular formula of C12H18 and a molecular weight near 162.27 g/mol. Insolubility in water keeps handling focused on sealed transfer, since leaks don’t simply wash away. Its solubility in ether, acetone, and other nonpolar solvents gives broad compatibility with laboratory workups and plant-scale processing. The compound holds relatively low reactivity at room temperature, but the two isopropyl groups set up for oxidation or further alkylation under catalytic conditions. Rigorous analytical testing, typically using GC or HPLC, tracks batch purity, flagging trace mono- or tri-isopropylbenzene or other ring isomers.

Tight technical specs drive the handling and acceptance of p-Diisopropylbenzene across producers and buyers. Most commercial batches aim for greater than 99.0% purity by area under gas chromatography, minimizing contaminants like cumene and higher branched isomers. Residual moisture typically sits below 0.1% due to the risk of hydrolyzing key intermediates downstream. Dove-tailing into chemical regulatory regimes like REACH in Europe or TSCA in the US, producers supply details of exact batch contaminants and lot numbers for every shipment. Drum and bulk container labels include not only basic identifiers and molecular formula but detailed hazard phrasing, handling instructions, and transport classifications to meet international standards. For anyone pulling samples in a QC lab or loading drums in a dock, these labels translate into everyday safety.

Manufacturers typically prepare p-Diisopropylbenzene by alkylating benzene with propylene, aiming for controlled temperatures and pressures to maximize para-isomer output. The choice of catalyst steers reaction selectivity: older plants ran with aluminum chloride, but modern sites favor zeolites or solid acid catalysts, which trim side-products and simplify waste management. Working at elevated temperature and moderate pressure, plant operators adjust reactant ratios and recycle heavier fractions back into the reactor to nudge yields. Stripping volatile impurities and fractional distillation sort out unwanted isomers and recycling streams. Over time, plant designers have prioritized both yield and environmental control, learning hard lessons in process optimization and economic return.

Chemists see p-Diisopropylbenzene as a handy launching pad for making dihydroxybenzenes, which underpin antioxidant production. A popular move involves oxidation of the isopropyl groups to afford p-diisopropylbenzene dihydroperoxide, which then cleaves to hydroquinone and acetone under acid catalysis. This step has served as a reliable industrial method for hydroquinone since the mid-20th century. Beyond that, electrophilic substitution can add more alkyl or functional groups onto the ring, while careful hydrogenation can walk down to less-branched derivatives. Some labs pursue Friedel–Crafts conditions to tack on bulkier side chains, aiming for increased solubility or alternative reactivity. The molecule’s structure reduces overreaction, letting chemists tune outcomes with more control than on simpler aromatics.

Some catalogs and chemical registries list p-Diisopropylbenzene as 1,4-diisopropylbenzene or para-diisopropylbenzene; old literature might call it p-DIPB. Commercial listings stick with the most descriptive names, which highlight isomeric purity, distinguishing it from its ortho and meta analogs. Product codes differ between suppliers, but the full chemical name nearly always appears on documentation, reflecting regulatory focus on unambiguous identification. Supply houses that serve high-purity markets sometimes tag it as a specialty aromatic hydrocarbon, drawing a clear line between grades. All these labels help avoid cross-ups in storage or reaction design, especially when bulk warehouses handle several similar-sounding aromatics.

p-Diisopropylbenzene calls for careful handling. The liquid can irritate skin and eyes, and inhaling vapors in concentrated form can bother the respiratory system. Flammability becomes a day-to-day concern, since vapors can ignite above the flash point, even if the compound itself seems stable. Proper personal protective equipment—gloves, splash goggles, and lab coats—should sit as standard for anyone pouring or sampling it. Handling protocols focus on containment, ventilation, and rapid clean-up of spills. Emergency response plans underline the importance of eye-wash stations and fire extinguishers staged near storage areas. Regulatory bodies like OSHA and the European Chemicals Agency have poured years into compiling guidance, and plant safety teams regularly refresh training based on real-world incidents. Shipping falls under UN1940, with labeling rules mapping onto broader hazardous goods guidelines.

Industry often draws on p-Diisopropylbenzene as a starting material for hydroquinone, which plays a key role in antioxidants, photographic developers, polymerization inhibitors, and specialty resins. Some producers turn to it for crafting other dihydroxybenzenes or custom antioxidants for plastics and rubber. Outside the chemical plant, some niche labs have crafted it into advanced intermediates for dye chemistry or fine fragrances that value aromatic stability. Its selectivity and reactivity allow for stepwise synthesis, giving process chemists flexibility to tweak reaction pathways and boost output or purity on demand. Most of its value arises behind the scenes—one link in a longer specialty chemical chain—but for those tracking component origins, its role can prove central to end-product reliability.

University groups and industrial teams remain curious about novel catalysts and greener production paths for p-Diisopropylbenzene. Zeolite-catalyzed alkylation has drawn attention for boosting para-selectivity while reducing corrosive waste, appealing to both environmental targets and process economics. Some labs study advanced separations, like membrane-based fractionation, to cut energy use downstream. Others in academia play with ring modification or isotopic labeling, seeking more informative mechanistic data or chasing entirely new derivatives. Partnerships between public research and industry consortia have improved data-sharing on safety, lifecycle impacts, and new synthetic transformations, laying a broader base for better stewardship and creative applications. Ongoing intellectual property filings suggest no one thinks development has stalled, even for such a focused compound.

Early toxicology raised concerns about aromatic hydrocarbons in general, pushing researchers to run targeted studies on exposure pathways and breakdown products. Animal testing, inhalation monitoring, and long-term biomonitoring programs have all shaped the data around p-Diisopropylbenzene. Acute exposure leads to irritation of mucous membranes, but chronic low-level contact prompts more study into possible neurotoxic effects or links with metabolic disruption. Most of the evidence to date points to limited long-term bioaccumulation, and no clear links to carcinogenic activity at industrial exposure levels. Nonetheless, updated occupational health guidance presses for monitoring of air concentrations and routine health surveillance for workers. Waste handling studies have mapped fate and transport in soil and water, urging waste disposal strategies that limit environmental release.

p-Diisopropylbenzene sits in an evolving landscape for specialty chemicals. Moves by global regulators toward safer solvents and greener synthesis shine a light on optimizing process steps, with real money flowing into research on catalyst recovery, byproduct valorization, and renewable feedstock routes. Market watchers track how shifts in demand for key downstream products, like high-performance antioxidants and resins, may reshape production volumes or pricing power. Broader adoption of continuous-flow processing unlocks new efficiencies for smaller-scale operations, allowing even mid-sized firms to join what used to be the domain of large plants. Integration with digital monitoring and data-driven yield analytics signals a future where both safety and output rise hand in hand. For those in charge of tackling legacy risks, safer handling and tailored containment drive upgrades at older sites, spurred by insurance standards and sharper liability rules. Researchers and industry alike keep one eye on emerging sustainable chemistry frameworks, seeking a foothold as both public health and environmental expectations stack up.

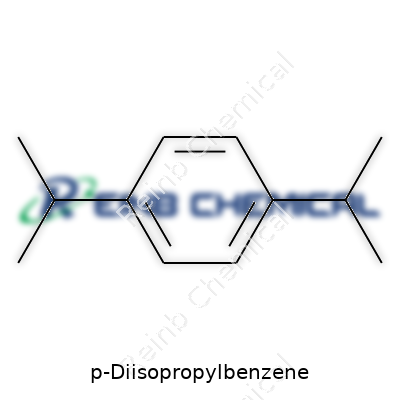

Chemistry often feels like a string of tough-to-pronounce names mixed with letters and numbers. Then someone brings up p-Diisopropylbenzene, and you remember that a lot of compounds with important roles in industry don’t always make it out of the classroom. The chemical formula for p-Diisopropylbenzene is C12H18. That formula tells you there’s a benzene ring at the core—six carbons in a hexagon, with hydrogen atoms around it. Add two isopropyl groups to the para positions on the ring, and you have this compound, C12H18.

In the real world, p-Diisopropylbenzene isn’t just a chalkboard curiosity. This compound plays a crucial role in the production of chemicals that end up in products from plastics to cleaners. Spend time talking to people in chemical manufacturing, and p-Diisopropylbenzene comes up—especially in the context of antioxidants, which keep plastics from breaking down. Antioxidants matter whether you’re concerned with a car dashboard surviving sun exposure or medical packaging staying stable on a shelf.

With p-Diisopropylbenzene, its specific arrangement makes it valuable as a starting ingredient for other compounds. Isopropyl groups stick out from opposite sides of the benzene ring, changing both the reactivity and how the molecule interacts with others. This simple shift in structure makes a world of difference for chemists who want to build larger molecules or steer a reaction in a safer, cleaner direction.

Take antioxidants like 2,6-di-tert-butyl-p-cresol (BHT). These go into things you use each day: food packaging, plastic bottles, rubber products. The manufacture of these antioxidants relies on building blocks like p-Diisopropylbenzene. I’ve seen manufacturers rely on supplies of this aromatic hydrocarbon to keep plants running efficiently and safely. A small error in sourcing or handling can mean a big headache down the road.

Handling benzenoid compounds can bring headaches beyond their chemistry. Benzene itself is a known carcinogen, and experts have learned from long histories of industrial use that vigilance matters. While p-Diisopropylbenzene is less volatile, companies must still control for vapors and waste, relying on strong safety protocols and monitoring. As someone who has worked in a plant environment, I learned quickly that carelessness around chemicals with benzene rings can lead to health issues or environmental releases.

Supply chains can also present a headache. Plants around the world sometimes face shortages or find themselves hunting for reasonably priced feedstock. Companies can run into regulatory changes or shifts in demand that push raw material costs upward. All this pushes the industry to hunt for improved synthesis methods. Green chemistry efforts have shown promise in reducing waste and finding safer catalysts. Tighter controls can help address safety, but research into less toxic alternatives is the best long-term win for reducing industry risk.

p-Diisopropylbenzene’s story highlights how chemistry reaches into daily life in ways people don’t always see. Regulators, manufacturers, and scientists do better work when they understand structure and risk. Focusing on safety, responsible sourcing, and continued research, everyone can benefit while keeping important materials flowing. Finding ways to reduce dependence on hazardous aromatics or shifting toward renewable sources could shape the future direction. Everything starts with understanding that small changes at the molecular level ripple out to large impacts, both in plant operations and in products people use every day.

p-Diisopropylbenzene doesn’t show up in most headlines, but it has found a comfortable spot in the chemical sector. Its most recognized value comes from its role as a starting material for other chemicals. Chemists working with aromatic hydrocarbons use it most often for the production of dihydroxybenzene compounds, especially hydroquinone and catechol. These aren’t just academic curiosities – they turn into ingredients for antioxidants, photographic developers, dyes, and specialty polymers. Hydroquinone finds its way into hair dyes, skin lightening creams, and even certain medicines. Catechol ends up improving flavors and stabilizing rubbers.

This compound holds a sweet spot between reactivity and stability. Its structure, with two isopropyl groups attached to a benzene ring, helps steer chemical reactions in a way that makes processes more efficient. Factories that manufacture high-purity hydroquinone use oxidation of p-Diisopropylbenzene because it works on a scale that justifies investment. By delivering consistent conversion, this method wastes less material and keeps byproducts to a minimum. Lower waste tallies up to real environmental and cost benefits, something that plants and regulatory bodies both appreciate.

The reach of p-Diisopropylbenzene stretches far beyond the boundaries of laboratories. Some of the rubber stabilizers in car tires can trace their origins to this molecule. It also pops up indirectly in plastic production, as some antioxidants come from its derivatives. In food packaging and other uses that require materials to stay stable and durable, the downstream chemicals produced from p-Diisopropylbenzene make a meaningful difference in keeping things fresh, or at least unchanged, for longer periods.

Water treatment technologies also benefit. Catechol made from p-Diisopropylbenzene can bind to heavy metals and toxins, making it easier to filter out harmful stuff before water flows through municipal taps. It is not as visible as chlorine or filtration, but it means safer water for many people.

Production relies on catalysts that sometimes carry their own environmental costs. With tighter regulations, chemical companies need to rethink older processes. Cleaner catalysis means less pollution for workers and communities living near production sites. There is real promise in research towards using renewable feedstocks or reducing the footprint of synthesis. My own time working with specialty chemicals has shown that incremental improvements in chemical pathways make a bigger difference than splashy innovations that never scale up. In regions where industry standards lag behind, there’s a chance for businesses to leap forward by adopting greener production.

Safety is never far from anyone’s mind in a chemical plant. p-Diisopropylbenzene itself is less toxic compared to some industrial chemicals, but attention to safe storage and handling always matters. Modern facilities use sensors, training, and rigid protocols to limit possible leaks or exposure. The chemical industry has learned from its past; keeping risk low goes hand in hand with maintaining public trust.

Very few people ever see p-Diisopropylbenzene on a label, but its derivatives touch medicine, water, and even transportation. The ways this compound gets used show how quiet building blocks can influence entire industries. Better production standards, responsible waste handling, and investments in cleaner synthesis offer a path forward for people working with or affected by this chemical. It stands as a reminder that the things crafted at an industrial scale have ripples — from local economies to global supply chains and, ultimately, to the end-users who never see the name but benefit all the same.

People in chemistry or industry circles sometimes work with substances like p-diisopropylbenzene, which shows up in the process of making antioxidants, detergents, and specialty resins. On the surface, it looks like another aromatic hydrocarbon, a clear liquid carrying a faint odor. Most who spend some time around industrial materials get used to that part. Underneath, the questions start: does this ingredient pose a risk to people, or to the world outside the factory fence?

I’ve seen product safety sheets recommend goggles, gloves, and working with proper ventilation. p-Diisopropylbenzene gets labeled as an irritant, which means splashes in the eyes or on skin do result in unpleasant reactions. If someone breathes in enough vapor, headaches and dizziness become real possibilities. Long-term studies on humans are scarce, so people lean on protocols designed for other aromatic hydrocarbons with similar properties. Benzene, to name one, brings up alarms for cancer risk, though p-diisopropylbenzene doesn’t meet the same classification right now. Caution isn’t a formality here – it’s just the routine when working with organic solvents.

In factories and labs, people worry about fire first. This chemical’s flash point hovers around 132°C, which counts as flammable, not explosive. Some older labs have tight enclosed spaces, and even a chemical considered moderately flammable leads to strict storage rules. Many accidents happen because someone gets casual or skips a check. Equipment for handling solvents involves spark-proof switches and double-checking containers stay sealed. Fire isn't a maybe – it remains a constant risk where large drums and poor ventilation mix.

Once the chemical heads out the door as waste or falls through a leak, the problems shift outdoors. Spills look like a small deal until rain carries everything into storm drains. Aromatic compounds don’t break down in water quickly. Once in the soil, some pieces stick around for months, possibly years. Fish and micro-organisms react badly to even mild contamination. The Environmental Protection Agency tracks releases of many similar chemicals, noting persistence and impacts on aquatic life. Even outside large-scale disasters, smaller routine leaks add up over decades, harming small streams and groundwater.

Risk control works best through proper management, not simply adding new warning signs. In jobs I’ve watched, regular maintenance checks, proper waste handling, and solid staff training keep dangerous situations rare. Some companies invest in substitute chemicals with fewer environmental downsides or invest in closed-loop systems, which make sure waste streams don’t escape. Regulations matter, but so does a culture that treats every spill and inhalation risk seriously, even if nobody feels sick right away. More research on long-term exposure would give everyone a clearer sense of the stakes – but lack of data shouldn’t mean the green light for careless use.

If you spend any time in a chemical storeroom or lab, you develop a certain respect for liquids like p-Diisopropylbenzene. The clear, oily look leads some to treat it like it's just another solvent, but behind that appearance sits a set of real concerns. I once saw someone assume p-Diisopropylbenzene was as harmless as vegetable oil because of how it handles in the lab. They learned the hard way: familiarity breeds mistakes, and chemicals don’t care how long you’ve been around them.

Where this chemical spends its life makes all the difference. Heat nudges volatile chemicals into dangerous territory. Storing p-Diisopropylbenzene at normal room temperature, out of direct sunlight, cuts the risk of slow breakdown and vapor pressure build-up. Warm storerooms increase evaporation, raising flammable vapor levels. At the other end, frigid temperatures thicken the fluid, making it tougher to handle safely. A steady 20°C gives you control instead of surprise. Keeping it away from direct light helps limit peroxide formation over time—the stuff you don’t want happening behind your back.

I once saw a bottle crack just because no one checked the chemical compatibility chart before choosing shelving. p-Diisopropylbenzene gets along with glass and certain plastics (high-density polyethylene, for example), but it bullies other materials into slow decay. Keep it in tightly-sealed containers, checking those seals once in a while to stop slow leaks. Plastic drums without proper venting bloat fast if the vapor collects, so you want tight but vented storage. Placing containers at eye level, not underfoot, means less risk of drops or tripping in a rush.

Anyone who stores flammables knows open flame should stay a mile away. With a low flash point, p-Diisopropylbenzene catches fire easily. Separate it from oxidizers—like industrial bleach or peroxides—since mixing or spillage can drive dangerous reactions. A flammable storage cabinet fitted with vents and grounding wires handles any vapor that tries to escape, reducing explosion risk. Lab coats are fine, but focus on goggles and splash-resistant gloves to cover skin. Small messes soak into rags or floor tiles and leave behind invisible vapors, so prompt clean-up matters. If you smell strong aromatic fumes, step outside and check that ventilation system.

Sloppy labeling lands people in emergency rooms. Every bottle needs a chemical name in plain view. Emergency eyewash stations and showers close at hand save vision and skin if someone spills. Exposing yourself and the team to regular safety reviews keeps these steps fresh. If a spill happens, using absorbent pads with a full respirator and gloves avoids breathing in nasty fumes. Disposal in a proper hazardous-waste system keeps local water and soil clean—never dumping down a drain.

Trickiest part of dealing with p-Diisopropylbenzene is getting new people to take it seriously. Sharing stories about close calls or showing videos of chemical accidents pushes the message home more than warnings on a page. Respect for the contents of each container—earned through training and those everyday habits—remains the best method to keep everyone healthy and the workplace out of the local news. Real safety happens in the quiet choices: checking lids, reading labels, and never rushing a task. The right attitude makes all the difference with chemicals like this.

Every time you buy or sell a chemical, you come across something called a CAS number. For p-Diisopropylbenzene, the CAS number is 99-62-7. I’ve filled out more safety data sheets than I care to count, and one thing became clear early: the CAS number isn’t just a detail—it’s how labs and suppliers keep track of what’s actually in the barrel or bottle.

I learned quickly that names can get muddled. Trade names, synonyms, and translations add confusion fast. The CAS Registry Number, assigned by the Chemical Abstracts Service, clears all that up. Call it a global shortcut. In production runs, paperwork, and audits, the CAS number stands tall as the unique, unchanging identifier.

With p-Diisopropylbenzene, often used in specialty chemicals and as a precursor in plastics or resins, mistakes in handling could mean lost money and safety hazards. I once saw a shipment held up for days because someone put “1,3-diisopropylbenzene” on paperwork, which raised eyebrows until we pointed to that CAS number printed on the barrel. Instantly, everyone was on the same page.

It’s hard to overstate how the CAS number supports safety. If you’re working with p-Diisopropylbenzene, knowing “99-62-7” gives you a direct path to the right safety protocols, regulatory guidance, and emergency information on the spot. Mismatching chemicals because of a typo brings disaster, especially for companies running lean with staff who don’t know every synonym by heart.

On the material safety data sheets, regulators, handlers, and even the IT department all use the CAS number as a single source of truth. This number links straight to REACH dossiers, EPA reports, and GHS classifications. Miscommunication in storage led once to mixing up two lookalike drums. The right CAS number averted a shutdown and a fine—one of those moments you remember during audits.

In a world where digital systems control inventory, the CAS number helps track the flow of chemicals from manufacturer to end-user. Automated barcode scanners and smart labeling systems all depend on exact matches to these numbers. It cut my own inventory audits from days to hours. Instead of searching product code after product code, every shipment flagged “99-62-7” unambiguously.

Research databases sort information by CAS number. Need a peer-reviewed paper on p-Diisopropylbenzene? Searching by 99-62-7 yields every study and toxicological review that’s ever been logged. That small number, just seven digits long, simplifies literature searches and patent reviews for everyone using it.

So how can organizations keep things error-free? Regular in-house training goes a long way, getting staff to memorize and verify CAS numbers before moving or mixing chemicals. Quick-reference charts and laminated sheets by the storage area saved my team time and cut down on mistakes.

On the tech side, chemical management platforms pair the CAS number with every purchase order, delivery receipt, and disposal note. Some companies now integrate QR codes with CAS numbers for instant lookups using a smartphone. That small change prevents wrong shipments and costly compliance errors.

Respect for the CAS number, like “99-62-7” for p-Diisopropylbenzene, developed after seeing near-misses and catching small errors before they grew. Forging a strong protocol around these numbers boosts safety, sharpens compliance, and saves money across the whole value chain.

| Names | |

| Preferred IUPAC name | 1,4-Diisopropylbenzene |

| Other names |

1,4-Diisopropylbenzene p-DIPB para-Diisopropylbenzene |

| Pronunciation | /ˌpiː daɪ.aɪ.səˌprəʊ.pɪlˈbɛn.ziːn/ |

| Identifiers | |

| CAS Number | 99-62-7 |

| Beilstein Reference | 633874 |

| ChEBI | CHEBI:33161 |

| ChEMBL | CHEMBL15805 |

| ChemSpider | 12263 |

| DrugBank | DB04245 |

| ECHA InfoCard | ECHA InfoCard: 100.011.716 |

| EC Number | 201-189-6 |

| Gmelin Reference | 82855 |

| KEGG | C06533 |

| MeSH | D008198 |

| PubChem CID | 6942 |

| RTECS number | GU5950000 |

| UNII | H0530V599B |

| UN number | UN2329 |

| Properties | |

| Chemical formula | C12H18 |

| Molar mass | 190.30 g/mol |

| Appearance | Colorless liquid |

| Odor | Aromatic |

| Density | 0.864 g/cm3 |

| Solubility in water | insoluble |

| log P | 4.80 |

| Vapor pressure | 0.22 mmHg (25°C) |

| Acidity (pKa) | 40.1 |

| Basicity (pKb) | basicity (pkb) = 19.54 |

| Magnetic susceptibility (χ) | -79.7·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4901 |

| Viscosity | 1.31 cP (20°C) |

| Dipole moment | 0.61 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 322.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -116.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6217.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P243, P261, P264, P271, P273, P280, P301+P312, P302+P352, P304+P340, P305+P351+P338, P312, P337+P313, P403+P235, P501 |

| Flash point | 107 °C (225 °F; 380 K) |

| Autoignition temperature | 424 °C (795 °F; 697 K) |

| Explosive limits | Explosive limits: 0.7–5.0% |

| Lethal dose or concentration | LD50 oral (rat) 3300 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 3300 mg/kg |

| NIOSH | KN7075000 |

| REL (Recommended) | 50 mg/m³ |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Benzene Cumene Cymene 1,4-Diisopropyl-2-methylbenzene |