M-Diethylbenzene didn’t get much attention in the chemistry world at first. Chemists in the late 1800s aimed to separate and catalog aromatic hydrocarbons, finding diethylbenzenes among them. The synthetic roots go back to the commercial expansion of the petrochemical industry, particularly after World War II, when folks realized derivatives of benzene could open new doors. The story of m-diethylbenzene fits into the rise of industrial aromatics. As demand for high-octane fuels grew, so did interest, because the side products from alkylation and reforming included m-diethylbenzene. Its history stays tied to the pace of refining and feedstock improvements, which kept it affordable for both research labs and manufacturers.

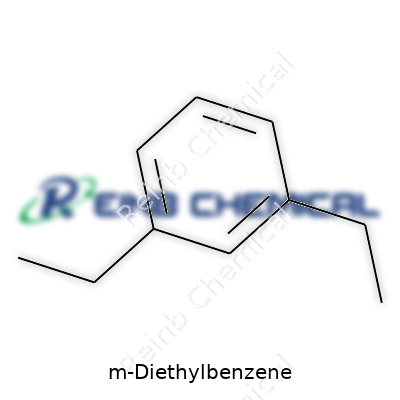

A lot of people might walk by a drum of m-diethylbenzene at a plant and never give it a second thought, but this clear liquid plays a behind-the-scenes role in all sorts of industries. The molecule carries two ethyl groups on a benzene ring, positioned at the meta locations. This set-up gives it different properties than its ortho and para cousins. The chemical industry keeps it around for making specific intermediates, and it shows up in sectors from flavors and fragrances to specialty solvents. Knowing its quirks has helped engineers and formulators grab the product for jobs where it outshines other solvents and aromatic hydrocarbons.

M-Diethylbenzene wears its chemistry on its sleeve. At room temperature, this compound sticks to the liquid state and stays colorless. Its boiling point usually falls around 183°C, a notch that chemists remember when designing separations. The molecule barely mixes with water, but handles nonpolar solvents like an old friend. Density sits at 0.867 g/cm³. The vapor pressure leaves something to be desired—people working with it indoors need proper ventilation. You can pick up its mild aromatic scent in even small leaks. Because those ethyl side chains stick out, reactions with oxidizers, halogenation agents, or even sulfonating mixtures often go faster and more cleanly compared to unadorned benzene.

Regulatory and quality teams give m-diethylbenzene a long look before letting it out the door. Purity typically needs to hit the 98% mark or above for most industrial uses. Any supplier worth the name tags the containers with the proper chemical name and hazard markings. Standards like the CAS number, UN transport code, and flammability warnings follow strict rules in chemical logistics. Whether the product ends up in a lab bottle or rail tank car, workers double-check those labels—as missing or incorrect data can spark problems down the line, both in safety and compliance.

Refiners and chemical plants rarely reinvent the wheel in making m-diethylbenzene. The main path starts with the alkylation of benzene using ethylene—catalysts like aluminum chloride or zeolites keep things humming. The challenge involves steering the reaction so the ethyl groups stick closest to the meta positions, which doesn’t just happen on its own. Plants separate the ortho, meta, and para forms using high-efficiency distillation columns. Each tweak in pressure, temperature, and catalyst tips the balance toward the meta isomer, but it still arrives mixed with its neighbors. Final purification steps round out the process, pulling a nearly clear product ready for use or resale.

Chemists love working with m-diethylbenzene because of those ethyl arms. Oxidation turns the ethyl groups into acids with a little help from air and catalysts, giving access to terephthalic- or isophthalic acids if you start with the right isomer. Halogenation can bring chlorine or bromine into the mix, swapping out hydrogens on the aromatic ring to open the way for other valuable intermediates. Nitro derivatives arrive under simple conditions, priming the molecule for reduction into useful amines for dyes and pigments. Even hydrogenation holds its own, saturating the ring for more specialized applications.

Chemistry doesn’t make it easy with names. M-Diethylbenzene pops up in catalogs as metadiethylbenzene, 1,3-diethylbenzene, and even m-DEB. CAS 141-93-5 helps clear up confusion, especially in global trade. Some specialty suppliers push trade names or house brands, hoping to lock in customer loyalty, but most folks working in facilities or labs stick to the standards for safety and traceability.

Anyone handling m-diethylbenzene has faced the hazards firsthand. The liquid catches fire below 50°C, so open flames and hot surfaces spell trouble. Despite its sweetish smell, overexposure leads to headaches and irritation. Gloves and goggles come standard, since skin contact dries and reddens skin in short order. Storage stays away from oxidizers and strong acids, with canisters parked in cool, vented spaces. Industry sets occupational exposure limits for the vapor, and training drills stress cleanup of spills before someone breathes in too much vapor. Disposal walks the regulated line, moving toward thermal destruction or treatment as hazardous waste.

Industry finds plenty of places for m-diethylbenzene. It creeps into the solvent blends used in coatings, inks, and resins. Manufacturers using it for synthesis appreciate the predictable reactions compared to trickier aromatics. Laboratories tap it as an internal reference or carrier for GC/MS work, enjoying its low background noise. Researchers reach for it in the hunt for new ligands or catalysts. Sometimes specialty cleaners, adhesives, or polymer processes lean on it for its balance of solvency and volatility. Even niche sectors in the fragrance world chase after pure samples, using its undertones or as a building block for more complex creations.

Scientists keep pushing the boundaries, figuring out fresh applications for m-diethylbenzene. Green chemistry teams tinker with milder routes for its synthesis, aiming to cut waste and energy consumption. Others take the structure and bolt on new groups, chasing potential in pharmaceutical or material science circles. Separations chemists keep testing purification techniques, from advanced membranes to selective crystallization, to push purity even higher. Each improvement, no matter how small, trickles down to pilot plants and then to full-scale operations, ultimately shaping the next generation of aromatics.

Workplace health studies keep a close eye on the impact of m-diethylbenzene. Acute exposure numbers suggest low toxicity compared to other aromatics, but chronic effects remain a concern in environments with poor ventilation or frequent spills. Researchers track metabolic pathways, noting how breakdown products behave in the body. Some evidence links aromatic hydrocarbons to liver and kidney stress, so safety data sheets keep evolving as fresh studies roll in. Personal experience in the lab has shown the need for respect—quickly wiped spills, prompt air exchanges in fume hoods, and never skipping the gloves. Regulatory agencies, building on new research, have kept the compound on observation lists to balance industrial value with worker safety.

The world doesn’t stand still, and the story of m-diethylbenzene still unfolds. Demand tracks the growth of coatings, inks, and advanced materials. Renewable feedstocks and green chemistry approaches, now at the edge of the industry, look ready to change the production pipeline. Some research hints at new uses in organic electronics and as custom reaction media for high-value synthesis. Digital process control and better analytics let suppliers dial in tighter specs, reducing off-spec batches and boosting efficiency. Efforts in recycling, recovery, and environmental stewardship may soon shift its life cycle. Keeping an eye on trends, it’s safe to say anyone in specialty chemicals or petrochemicals will watch m-diethylbenzene’s path for years to come.

m-Diethylbenzene doesn’t come up in conversation around the dinner table, but in chemical plants, it plays a big part. Companies in the chemical industry use this compound to manufacture ingredients found in plastics, dyes, and resins. m-Diethylbenzene acts as a building block for much larger molecules. High-volume industrial processes tap into its ability to transfer ethyl groups easily, sparking reactions used to create specialty chemicals.

Anyone who’s worked with paints or adhesives understands the struggle of finding a liquid that can break down tough substances. m-Diethylbenzene steps in as an effective solvent for waxes, oils, and resins. In my own experience dealing with industrial cleaning, compounds like this help dissolve residues manufacturers struggle to remove. Reducing stuck-on contaminants means less time cleaning and less money spent on expensive downtime.

Labs seek out m-Diethylbenzene as a reagent. Certain syntheses require a specific structure or reaction pathway, and having m-Diethylbenzene on hand offers scientists more creative freedom. In a small research lab I visited last year, chemists used it as an intermediate to develop custom flavor chemicals for the food industry. m-Diethylbenzene gave them both the reactivity and structure they needed, which they couldn’t get from simpler solvents like toluene.

Big pharmaceutical companies carefully select their intermediates. m-Diethylbenzene enters this arena by acting as a step between basic chemicals and complex medicines. Its stability at higher temperatures ensures safe, predictable reactions, especially for creating anti-inflammatory drugs or specialty polymers in medical devices. Safety engineers and regulatory authorities keep a close eye on quality and production controls, so each batch must meet strict standards—less contamination, greater reliability.

Chemicals like m-Diethylbenzene come with heavy responsibilities. I’ve seen firsthand how small leaks from storage tanks or mishandled drums can hit local groundwater. Regular training for staff and tightly sealed systems make a real difference. Environmental specialists often recommend regular inspections and immediate reporting of spills, aiming to avoid the problems seen in older facilities. Investing in modern containment and ventilation keeps workers safer and reduces risk of air pollution.

Public interest in cleaner chemistry keeps growing. Some companies already experiment with plant-based solvents or design new processes that cut toxic emissions. Regulatory bodies like the EPA push for less hazardous compounds in manufacturing. Creating safer alternatives doesn’t always come cheap or easy, but collaboration between researchers, government, and industry spurs invention. Real progress means safer products and fewer headaches for workers and the environment. Attention to sustainable chemistry stands out as the most practical path forward.

In organic chemistry, the way molecules are arranged often means more than just the sum of their atoms. m-Diethylbenzene, with the chemical formula C10H14, is a great example. The “m” stands for “meta,” showing where the ethyl groups sit on the benzene ring: separated by one carbon atom. It’s not just a trivia question for a college exam—understanding this arrangement makes a real difference in how the molecule behaves and why chemists pay attention to it.

Back in my university lab sessions, I quickly learned that placement of groups on a benzene ring could change the way a compound reacted. Sometimes it felt like a little mystery—the same atoms, but different connections would change smell, boiling point, and usefulness. With m-Diethylbenzene, those two ethyl groups attach at the 1 and 3 positions. This setup sets it apart from its cousins, o-diethylbenzene and p-diethylbenzene, where the groups are next to each other or across the ring.

That difference changes more than just a name in a textbook. The spacing affects physical properties. For instance, m-Diethylbenzene boils at about 181°C. The other isomers have slightly different boiling points. Mixing these up can mess up an experiment or industrial process. The chemical formula, C10H14, covers them all; the arrangement is what separates them. This highlights the importance of paying attention not just to numbers, but to how those atoms fit together.

While some folks only see it as an answer to a test question, industries use m-Diethylbenzene as part of solvent blends and as a building block for making other chemicals. Growing up near a refinery, I always heard about how these sorts of molecules end up in paints, varnishes, and specialty fuels. So, these “little differences” carry weight far outside the stuffy walls of chemistry departments.

Ignoring details in chemical formulas can cause headaches. Many safety protocols depend on knowing exactly which molecule is in use. In the early days of my lab work, using the wrong isomer led to a batch that couldn’t be used—costing money and time. That experience stuck with me. Knowing the formula C10H14, and checking the structure, isn’t just about ticking off requirements. It means safer work conditions, reliable results, and the ability to predict how a material might behave in new applications.

On a broader scale, the way we track and share information about substances like m-Diethylbenzene reflects larger trends in responsible science. The demand for transparent data, rigorous checks, and sharing expertise helps protect both workers and the environment. Google’s E-E-A-T guidelines touch on this by valuing experience, authority, and trust in how we share facts.

To get the most out of chemistry, experience matters. Double-checking formulas, understanding structural differences, and talking with experts all help avoid costly mistakes. Sharing knowledge and sticking to high standards means fewer mishaps and better results, whether in the classroom, lab, or on the factory floor. For anyone handling organic molecules, small details matter—a lesson I learned by trial, error, and a few ruined experiments along the way.

Most people won’t recognize m-Diethylbenzene from everyday conversation. This chemical shows up in certain industrial processes and sometimes in the labs where chemists synthesize other compounds. Like many compounds derived from benzene, m-Diethylbenzene comes with its own concerns, especially once it leaves the controlled environment of a lab or factory.

Someone who has spent any time working near solvents and aromatic hydrocarbons quickly starts to respect both the benefits and potential dangers of these chemicals. A lot of us ask if a given solvent could impact our breathing, irritate our skin, or worse, cause long-term health issues with enough exposure. m-Diethylbenzene, with a structure not too far from xylene or toluene, can raise those same questions.

Aromatic hydrocarbons have a reputation for vaporizing at room temperature. For anyone handling m-Diethylbenzene, this means fumes can sneak into the air, creating how-it-smells problems and, more important, health issues after breathing them for too long. Eyes and nose might start to burn, and some people could get headaches if ventilation isn’t cutting it. That’s the short-term side.

Long-term or repeated exposure deserves special attention. Many hydrocarbons related to benzene carry the risk that over time, with enough contact, they might affect the nervous system. Benzene itself is notorious for causing blood problems after chronic exposure. m-Diethylbenzene hasn't been pinned with such heavy charges in the research, but the lack of robust studies doesn’t mean a free pass. The American Conference of Governmental Industrial Hygienists recommends caution because similar chemicals have turned problematic in the past.

Skin contact creates its own problems too. Defatting—what some call the drying and cracking of skin after regular exposure to solvents—can show up pretty quickly, especially if proper gloves miss the scene.

Spilling m-Diethylbenzene in a busy lab or workspace isn’t the whole story. If it enters the air or finds its way into water systems, it sticks around longer than expected. Microbes aren’t fast at breaking it down, so wildlife and people living near factories face a bigger risk. This raises another red flag when considering broader health implications.

Straightforward solutions often have the most impact. Good ventilation makes a difference. Anyone handling drums or bottles should reach for proper gloves, splash goggles, and maybe a respirator if fumes seem heavy. Routine air checks in workspaces help spot problems before anyone gets a headache or worse.

Shifting away from open containers or using smaller amounts only when absolutely needed can cut risk quickly. Many workplaces fit local exhausts above benches and train their workers to clean up spills right away. This doesn’t make m-Diethylbenzene harmless, but it lowers how much staff breathe or touch. Labeling containers and keeping a tight inventory cuts down on confusion that can lead to problems.

The bigger picture for anyone using or living near facilities handling m-Diethylbenzene involves holding companies accountable. Reporting leaks and keeping federal guidelines strict draws a clear line about what matters more: health or the bottom line. No chemical brings zero risk, but lifting awareness and nudging both individuals and companies to address these risks head-on protects the community in the long haul.

m-Diethylbenzene, known among chemists as one of the isomers of diethylbenzene, is a colorless, aromatic liquid. Its scent carries that sweet, familiar tinge often recognized in industrial solvents. This sort of compound doesn’t only catch attention in laboratories. It shows up in industries, manufacturing sites, and sometimes even in technical hobbies involving organic chemistry.

With a boiling point usually hovering around 181–183°C, m-Diethylbenzene handles heat pretty reliably. That means it doesn’t drift off into vapor at room temperature. You need a serious bump in temperature before it starts to boil. Its melting point stays low, around −22°C, which means in most climates, it’ll stay liquid unless dealing with freezing conditions.

These properties shape its role in the chemical world. Compared to other isomers, the boiling point places it in a spot where transportation and handling call for awareness but do not pose extreme demands. In my experience visiting chemical processing plants, these details get checked and double-checked because leaks or spills don't just vanish, especially with aromatic hydrocarbons in the mix.

Density for m-Diethylbenzene sits around 0.86 grams per cubic centimeter at 20°C. Pour some into water, and you’ll see it floats, refusing to dissolve. That comes from its non-polar nature; water just doesn’t welcome it in. So in industrial use, accidental spills usually get cleaned by skimming, not dissolving or dilution.

For those who deal with liquid storage or transport, density measures end up practical. Tank sizes, flow rates, and even emergency procedures take density into account. I’ve seen shipping companies adjust volume calculations based on this single figure; a mistake there turns into logistical headaches or even safety issues along the line.

Viscosity is low. The liquid moves with ease, looking almost like water in motion rather than a thick oil. You won’t need special piping or tricky pumps. Vapor pressure, another significant number, comes in at about 0.2 kPa at 20°C. This shows that it doesn’t evaporate quickly under moderate conditions. Still, proper ventilation stays necessary, as even small amounts of vapor can irritate.

I’ve watched storage managers keep careful tabs on vapor pressure because ignoring it can lead to risky buildups of fumes, especially in storage tanks or enclosed spaces. Good design and safety checks lower the odds of inhalation hazards or, worse, explosion risks.

These physical properties aren’t just facts for textbooks—they guide how m-Diethylbenzene gets shipped, stored, or handled in industries. Laboratories want purity and predictability. Industry wants efficient, safe, and cost-effective options. Because of the low water solubility and moderate boiling point, you’ll see this compound used where water interference could cause trouble, or where separating out a component quickly and efficiently makes the whole process run smoother.

In my own time shadowing chemical engineers, we discussed substitutes for cost or regulatory reasons. m-Diethylbenzene often showed up on those lists—not as the cheapest, but as one that brought predictable performance. Controlling storage temperature and providing proper personal protective equipment (PPE) prevents most problems.

By treating m-Diethylbenzene with the same respect given to other volatile organic compounds, risks shrink. Good training, frequent checks, and straightforward protocols carry more impact than any fancy device. The right measures—continuous monitoring, spill containment, and responsible disposal—mean that the physical properties of m-Diethylbenzene work in your favor instead of against you.

Working in chemical manufacturing, I’ve seen m-Diethylbenzene show up as a colorless liquid with a faint, sweet odor. Its flammability often goes understated. In some labs, I recall seeing open containers stored near sources of static electricity, which nearly led to disaster. The flash point sits around 62°C (144°F), which means a hot warehouse or careless spark can ignite vapors faster than people expect.

I read CDC’s listings that point out m-Diethylbenzene inhalation leads to dizziness and headaches. Breathing the vapors for long periods weakens concentration, and higher doses can impact the nervous system. Absorbed through the skin, this chemical also dries and irritates after short exposures.

People too often underestimate its environmental threat. Like other hydrocarbons, spills run off into drains and streams. Toxic effects build up in aquatic organisms, so even a small drip puddling under a barrel can harm downstream life. From what I’ve observed, many accidents trace back to routine carelessness rather than large-scale negligence.

Proper storage starts with a sturdy, fireproof cabinet or warehouse, preferably with spark-proof fixtures. Metal shelves and floors collect static, so grounding is a must. The right approach uses explosion-proof electrical wiring. Drums and containers need certified seals and clear hazard markings. Stack them no higher than shoulder-height, so grabbing or moving one barrel does not lead to collapse.

Ventilation does most of the heavy lifting inside small chemical rooms; stale air means vapors cluster and raise risk. In facilities where I’ve worked, small extract fans proved invaluable, drawing away invisible fumes. Even changing filters on these fans made a difference, especially after peaks in production.

PPE isn’t optional. Goggles and nitrile gloves provide basic protection. Tyvek coveralls come in handy for high-volume transfers, acting as both spill prevention and health insurance. Safety shoes keep toes safe if a container slips. I’ve seen workers skip gloves on hot summer days — only to show up at the nurse’s station later.

One leak taught me more than any manual. After a crack formed in a storage drum, sudden vapors sent three people to the exit gasping for air. Speed made all the difference. Every second counts. Getting the room clear, using absorbent pads and airing out the space finished the job. Emergency instructions on the door, regularly updated, cut confusion.

Fire extinguishers rated for organic solvents — think foam, dry powder, or CO2 — should always stay within reach. Water sprays do little and often spread the chemical farther; I saw one spill multiply across the floor because someone grabbed the wrong fire hose.

Training goes beyond checklists. People remember hands-on drills much longer than they recall a slideshow. Practice with spill kits and actual PPE makes the routine more real. Regular reminders on the wall reinforce caution, not paranoia. I’ve found checklists on the door emphasize preparation without overwhelming with details.

Simple changes — secondary containment trays, clear labeling, or a quick morning safety huddle — reinforce the habits that hold accidents at bay. People come to trust process, not by rules alone, but by experience, shared stories, and the knowledge that everyone’s looking out for each other. Decades in the industry prove that small habits stop big problems.

| Names | |

| Preferred IUPAC name | 1,3-Diethlylbenzene |

| Other names |

1,3-Diethylbenzene m-Diethylbenzene |

| Pronunciation | /ˌdaɪˌɛθəlˈbɛnˌziːn/ |

| Identifiers | |

| CAS Number | 141-93-5 |

| Beilstein Reference | 637239 |

| ChEBI | CHEBI:34383 |

| ChEMBL | CHEMBL22852 |

| ChemSpider | 7173 |

| DrugBank | DB02183 |

| ECHA InfoCard | 100.123.346 |

| EC Number | 208-734-8 |

| Gmelin Reference | 794 |

| KEGG | C01604 |

| MeSH | C014324 |

| PubChem CID | 8248 |

| RTECS number | DI0175000 |

| UNII | YT7R5K6C2G |

| UN number | UN2277 |

| Properties | |

| Chemical formula | C10H14 |

| Molar mass | 134.22 g/mol |

| Appearance | Colorless liquid |

| Odor | Aromatic odor |

| Density | 0.867 g/cm³ |

| Solubility in water | Insoluble |

| log P | 2.81 |

| Vapor pressure | 0.62 mmHg (25°C) |

| Acidity (pKa) | 15.0 |

| Basicity (pKb) | 6.66 |

| Magnetic susceptibility (χ) | -67.6e-6 cm³/mol |

| Refractive index (nD) | 1.4906 |

| Viscosity | 0.813 cP (20°C) |

| Dipole moment | 0.61 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 240.6 J/(mol·K) |

| Std enthalpy of formation (ΔfH⦵298) | -19.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3877.8 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H304, H315, H319, H335, H336, H411 |

| Precautionary statements | P210, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 64 °C (147 °F; 337 K) |

| Autoignition temperature | 550 °C |

| Explosive limits | 1.0% - 6.7% |

| Lethal dose or concentration | LD50 oral rat 3000 mg/kg |

| LD50 (median dose) | LD50 (median dose): oral, rat: 4,300 mg/kg |

| NIOSH | KW3675000 |

| REL (Recommended) | 50 ppm |

| IDLH (Immediate danger) | 1000 ppm |

| Related compounds | |

| Related compounds |

m-Xylene m-Dimethoxybenzene 1,3-Diisopropylbenzene 1,3-Dibromobenzene |