People have been shaping the story of chemistry with their discoveries, turning simple molecules into the foundation for massive industries. Cumene emerged in the early 20th century as chemists worked on ways to turn fossil resources into products far more valuable than crude oil. The development of catalytic alkylation, especially by Charles Friedel and James Crafts in the late 1800s, opened the gate for linking benzene with propylene. By the 1940s, the value of cumene was clear. Producing phenol and acetone for plastics, resins, and solvents now had a chemical shortcut, and the synthesis fit right into the petrochemical toolkit. Not many molecules go from a byproduct of cracking processes to a centerpiece in modern manufacture, but cumene did just that. It reflects how a single discovery can ripple through economics and daily living, turning a laboratory curiosity into a building block for so many things people touch today.

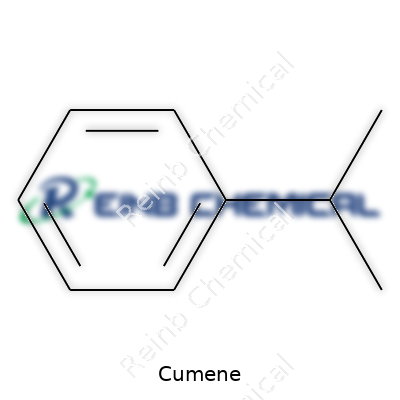

Cumene, known to chemists as isopropylbenzene, carries the badge of a key commodity chemical. Most of the cumene goes straight to facilities that produce phenol and acetone via the cumene process. Beyond that, the molecule serves as a valuable intermediate for organic syntheses. It's found in adhesives, coatings, synthetic fibers, and sometimes even in fuels as a high-octane booster. Its versatility anchors it in thousands of factories, with a global production total running into millions of tons each year. There may be flashier chemicals grabbing headlines, but cumene’s core role in the supply chain has been unshaken for decades.

Hydrocarbon chemistry doesn't always look flashy on paper, and cumene’s modesty only makes its utility more impressive. At room temperature, cumene is a colorless, oily liquid with a distinct aromatic smell; this scent stirs up immediate association with organic solvents and gasoline additives. It boils around 152°C, melts near -96°C, and dissolves poorly in water while mixing smoothly with most organic solvents. Chemically, cumene resists many reactions thanks to the stability of its benzene ring. The isopropyl group offers a handle, letting skilled chemists nudge it into various derivatives. Its vapors catch fire easily, so safe handling always becomes a concern in industrial settings.

Industry expects tight standards for bulk chemicals, and cumene’s technical profile matches those expectations. Purity above 99% is common for industrial lots, and reliable producers supply data on density, refractive index, and residual content of moisture, sulfur, and various aromatic or aliphatic impurities. The UN marks it as a flammable liquid, packing it under the code UN 1918. Material safety data sheets call out the flash point—typically above 30°C—the hazard code H226 for flammable liquid and vapor, and the need to avoid inhaling fumes or repeated skin contact. In packaging, storage involves tightly sealed steel drums or tanker trucks with careful grounding to shield workers from static discharge.

Making cumene at scale draws from a playbook refined over decades. Chemists blend benzene and propylene over acidic catalysts—often solid phosphoric acid or zeolites—at elevated temperatures and moderate pressures. Refineries fine-tune their operating conditions to strike the best balance between conversion and unwanted side reactions. After the main reaction, distillation columns split off unreacted raw materials and byproducts like polyisopropylbenzenes. Modern plants recycle both benzene and propylene again and again, squeezing every drop of value from their starting materials. The simplicity of the recipe masks the sophistication hiding in catalyst design and process control.

What makes cumene interesting in the eyes of synthetic chemists is how neatly it can be oxidized. In the flagship industrial process, cumene reacts in air to form cumene hydroperoxide, and this intermediate holds the door open for making both phenol and acetone, central ingredients for bisphenol A, polycarbonate plastics, and other key materials. Chemists draw on other reactions, too: Friedel–Crafts alkylations, oxidations, and even nitrations find use in specialized syntheses. With every tweak to the isopropyl group or aromatic ring, a whole portfolio of aromatic derivatives becomes accessible, feeding research programs into topics like fuel additives, antioxidants, and pharmaceuticals.

The chemistry community uses several names for cumene, like isopropylbenzene, 2-phenylpropane, and sometimes even “aromatics C9” in refining circles. Some suppliers stamp it under trade names specific to their product lines, but most buyers recognize the simple structure and rely on chemical, not branded, designations. Having a common language keeps risks low and trading easier for a global industry, especially when moving thousands of tons of material each year.

Working with volatile aromatics always brings safety to the forefront. Cumene needs careful handling because it forms flammable vapors above its flash point, and its fumes can irritate the respiratory system. Occupational safety rules call for good ventilation, spark-proof equipment, and protective clothing—items I’ve seen worn every day on busy plant floors. Safety data sheets recommend spill controls like sand and universal absorbents, with foam or CO₂ extinguishers ready in case of fire. Long-term exposure studies link repeated overexposure with central nervous system effects, so air monitoring and robust training form the backbone of safe operations. The regulatory environment keeps raising the standard, and responsible companies find it worth investing in continuous improvement, not just compliance.

Everyday objects quietly depend on cumene. Manufacturers use it to churn out phenol and acetone, which then supply resins, coatings, plywood adhesives, synthetic fibers, optical media, and hundreds more items. It works behind the scenes in automotive plastics, construction sheeting, and even pharmaceutical solvents. I’ve walked through facilities where the journey from a barrel of cumene becomes anything from a brake lining to a smartphone case. Some niche markets tap cumene as a fuel additive, seeking to boost octane without extensive modification to engines. Its role as an intermediate gives it staying power, even as trends in recycling or alternative feedstocks keep shifting.

Chemists and engineers keep looking for better ways to make, use, and recycle cumene. Newer catalysts offer higher activity and selectivity, which means fewer unwanted byproducts and less need for energy-hungry purification steps. Industrial labs study green chemistry angles, looking to lower emissions or swap out fossil-derived feedstocks with renewables. Advanced modeling and online monitoring tools help plants run closer to their limits, trimming costs and environmental footprints. Universities tap cumene chemistry when training future process engineers in kinetic modeling and scale-up studies, always searching for the edge that keeps them competitive in fast-changing markets.

Over the years, toxicologists have examined how cumene affects people and ecosystems. Acute exposure can cause headaches, dizziness, or irritation; chronic workplace exposure prompts care around lung, liver, and kidney function. Studies in animals suggest certain risks at high concentrations, leading regulatory bodies to set exposure limits and require monitoring in plants. Waterborne cumene biodegrades with the help of microbes, but local spills need prompt containment to avoid groundwater problems. Environmental scientists contribute ongoing studies to untangle how aromatic hydrocarbons like cumene break down and move through air and soil, steering policy and operational tweaks to limit exposure and risk.

Industries that rely on cumene keep evolving, facing pressures for cleaner, safer, and more efficient production. Some experts see a shift toward bio-based benzene and propylene as the next leap, letting refineries blend sustainability into legacy infrastructure. Process engineers see potential for even tighter process integration, using heat and mass transfer more effectively while reducing waste and emissions. Recycling phenol and acetone from post-consumer plastics could close the loop for these building blocks, hinting at a circular future where cumene plays a bridge between old and new economies. Investment in cleaner technologies, smarter catalysts, and broader risk assessments means the story of cumene is still adding new chapters, echoing its early history as a surprising breakthrough in applied chemistry.

Walk down the grocery aisle and grab a bottle of common household cleaners. Drill through an office park and take in the plastics holding together computers and furniture. Step outside after rain and catch a whiff of gasoline at the corner store. All of these pieces of daily life connect in subtle ways to a colorless liquid not many talk about—cumene.

Most of the cumene out there serves as a building block for two bigger names: phenol and acetone. Manufacturers crank out millions of tons of cumene every year, and almost all of it eventually ends up as phenol or acetone. That sounds technical, but the ripple effect reaches farther than folks realize. Acetone lands in nail polish remover, paint thinners, and cleaning agents. On the other side, phenol leads to plastics, most famously BPA and resins found everywhere from electronics to plywood.

For a few years, I worked at a plant where phenolic resins kept operations humming. People outside the plant never cared much about supply chain hiccups, but if a shipment of cumene got delayed, the effect could knock down production runs for weeks. Projects paused, workers lost overtime, and tension grew. That experience made me appreciate how vital these invisible chemicals are, even if they hardly grab headlines.

Folks living near chemical plants think about cumene a bit differently. Any material made on this scale—over twenty billion pounds worldwide each year—deserves a close look at how it's handled. Long-term exposure can cause headaches, dizziness or worse. The Environmental Protection Agency tracks levels near manufacturing hubs, and the industry spends a lot keeping vapors contained and pipelines tight. Spills and leaks sometimes happen, but tighter rules in big economies have slashed risks in the past two decades.

One thing that bugged me years ago: plenty of finished products hit store shelves with almost no chemist in sight, pushing safety concerns to the outskirts. Now, more attention falls on what goes into plastics and solvents. Consumers press for safer raw materials and transparent supply chains. Workers demand better protective gear and air quality inside plants. Industry regulators now use better sensor networks and enforce stricter penalties for polluters.

As demand for cleaner, greener production grows, chemical firms look at how cumene fits a changing world. Some researchers have worked on bio-based phenol and acetone, hoping to cut reliance on fossil fuels. Others rethink energy use—using renewables where possible—and recycling phenolic products at the end of life. These changes move slow, but they're picking up pace.

One small example: the shift toward water-based paints, less reliant on harsh solvents like acetone, has led to new research in how to make paints just as tough and long-lasting. Each push toward “greener” chemicals puts a spotlight on every link in that supply chain, cumene included.

Trust grows when experts share what goes on behind factory gates and take the time to address community worries with hard data, not jargon. Producers who offer clear information about chemical handling, environmental impact, and steps for safety build credibility. Engaged communities keep companies honest, drive innovation, and—over time—lift everyone’s health and quality of life. Cumene may not land in shopping carts directly, but its story matters to every product stacked on store shelves.

Cumene goes by the chemical formula C9H12. Chemists also call it isopropylbenzene. This formula might look simple, but it’s surrounded by deeper stories of industrial chemistry, everyday products, and health discussions.

Cumene forms the backbone for making phenol and acetone, two ingredients with deep roots in dozens of everyday materials. Factories make cumene by treating benzene with propylene, often using an acid as a catalyst in the reaction. According to the American Chemistry Council, over 11 billion pounds of phenol get produced every year, most starting from cumene. Phenol itself lands in resin, glue, and preservatives, while acetone pops up in nail polish remover, plastics, and cleaning products. Without cumene, the shelves of any hardware or grocery store would look pretty empty.

I worked for a few years in a small industrial lab, where chemical safety got drilled into daily routines. Every label got checked, fume hoods always ran, and gloves were a must. Cumene showed up on supply lists for tests and as a solvent. One thing that stuck with me—some people don’t realize these “hidden” chemicals drive so many products. Understanding its hazards leads to better safety at work and home.

According to the U.S. Environmental Protection Agency, cumene vapor irritates the eyes and respiratory system and, in high concentrations, causes headaches and dizziness. Long-term exposure has led regulatory agencies such as OSHA and NIOSH to set precise workplace exposure limits. Reading safety data sheets matters even for folks who don’t see themselves as “science people.”

Spills and emissions raise environmental flags for many industrial chemicals, cumene included. The compound can leak into water or soil during production, storage, or transport. While cumene breaks down fairly quickly in the air, it lingers in groundwater for a while. This risks contaminating wells and drinking water supplies. According to the ATSDR (Agency for Toxic Substances and Disease Registry), most people breathe in more than they drink from the environment—this puts added responsibility on factories and regulators.

Plants now lean on better leak-detection systems, double-walled tanks, and recycling techniques that keep more cumene from escaping in the first place. Some businesses invest in cleaner catalysts and push for closed-loop systems to grab and reuse gas before it slips out. Real change happens when regular inspections catch issues before they escalate, and employees feel safe reporting leaks or unsafe conditions.

People often miss that even things as ordinary as a laminate countertop or a bottle of acetone draw their life stories from chemicals like cumene. Choosing products from brands that publish responsible sourcing info can give consumers more power. Community members can join local environmental groups or attend city council meetings where industrial permitting gets discussed.

Knowing the formula alone—C9H12—only scratches the surface. Following a product’s path from raw ingredients to household shelf helps everyone make smarter decisions, both for personal health and the planet.

Walking into an industrial plant, you might catch a whiff of something sharp—maybe that's cumene, a chemical you probably haven’t heard about unless your job puts you close to tanks and pipes. It’s found in paints, varnishes, and as a step in making acetone and phenol. Down the line, it ends up in things like plastics and resins.

I’ve worked around industrial chemicals, so I know you can’t always see the danger, even if you smell it. Research shows breath and skin contact rank as main ways for cumene to enter the body. Inhaling high levels can cause headache, dizziness, and throat irritation. There’s documented evidence that once it gets inside, cumene can cause sleepiness and incoordination. Reports from the National Institute for Occupational Safety and Health (NIOSH) describe workers who ended up coughing or feeling sick after being around high concentrations, often in enclosed spaces.

Long-term exposure tells a different story. Animal studies with repeated doses link cumene to changes in the liver and kidneys. The US Environmental Protection Agency (EPA) notes that cumene is a possible human carcinogen because animal groups developed tumors under special conditions. Research hasn't proved it causes cancer in people, but having walked through safety briefings, I trust that we shouldn't take chances where science still has blanks.

Industry workers face more risk than folks at home. Most people don’t run into enough cumene to get sick because it floats away quickly in the open air, and home products contain low concentrations. Still, inhaling big doses makes people feel lightheaded or nauseous. The main danger shows up in poorly ventilated spaces, where vapors hang around.

It’s not only about sniffing fumes. Contact with skin can also cause irritation or even burns with enough exposure. I remember seeing coworkers cover up with gloves and masks. Companies keep safety data sheets handy, spelling out these hazards, asking people to pay attention, though in my experience, quick jobs sometimes tempt workers to skip steps. Those moments of carelessness can lead to health scares that last.

Wearing protective gear like gloves, goggles, and proper masks limits exposure right away. Real safety means more than just wearing the right outfit, though. I’ve learned that routine air monitoring catches leaks before they get dangerous. Good ventilation systems help, especially in small rooms where vapors can pile up.

Employers owe it to workers to run regular safety trainings, check up on equipment, and keep emergency wash stations working. Law backs this up—both OSHA and EPA set limits for workplace exposure. These regulations only help if people follow them. I’ve seen how clear rules and strict supervision can prevent accidents.

Not everyone deals with cumene daily. If your job brings you near it, informed caution makes a difference. Recognize symptoms such as dizziness or sore throat, and don’t hesitate to step outside and get fresh air. If you own property close to industrial zones, ask questions about their safety records and what they emit. Transparency from companies lets people feel confident in the safety of their homes and workplaces.

Anyone who’s spent time in the industrial heartland can see the tangible impact of chemical processes. Cumene production stands out because it helps bridge the gap between raw hydrocarbons and several building blocks of modern life. The journey starts with benzene and propylene, two compounds that often roll out of oil refineries. Throw those together, add a catalyst, and out comes cumene.

It might sound like chemistry class, but this process plays out on a scale that touches everything from plastic to cleaning products. Most plants rely on the Friedel–Crafts alkylation reaction. This reaction usually uses a solid acid catalyst, like zeolite, and runs at elevated pressure and temperature. Plants run continuously, tweaking heat and pressure to squeeze out as much cumene as possible.

Cumene doesn’t show up on shelves, but it powers industries behind the scenes. The real reason for its importance lies in what it becomes—phenol and acetone. These two find their way into paints, electronics, pharmaceuticals, and plenty of plastic goods. Companies crank out around 15 million metric tons of cumene every year worldwide. That's not just a number—it speaks to demand from countless finished products.

Trying to make phenol or acetone without cumene would push costs and waste up. Industry giants—whether in the States, Europe, or Asia—stick with this route because it runs efficiently and delivers solid performance. Decades’ worth of research keeps finding small ways to squeeze out more value with fewer resources.

Talking to anyone who’s managed a plant, it’s clear that production brings both reward and responsibility. Cumene plants draw their raw stuff from oil and gas. That ties this process to all the ups and downs of global energy markets. Supply crunches make it tough to balance quality, cost, and efficiency. Consider the struggle during energy shocks—chemical supply chains wobble, and local jobs can take the hit.

Environmental concerns shape the future too. Wastewater, volatile organic compounds, and carbon emissions draw attention from both watchdogs and neighbors living nearby. Nobody wants a plant fouling the next county, so industry leaders track tightening emission rules closely. In my days consulting around the Gulf Coast, plant managers knew a slip-up could mean a costly clean-up or even a shutdown.

Pressure grows to run cleaner and safer. Shifting to more efficient catalysts, like advanced zeolites, means less waste and lower energy bills. Closed-loop systems help trap and recycle byproducts, keeping emissions in check. Digital monitoring lets teams spot leaks early or adjust the process before things get out of hand.

Switching feedstocks mostly stays out of reach because bio-based benzene and propylene cost more for now. Some labs tinker with renewable options, hoping prices drop as technology matures. Until that day comes, most fixes focus on tightening the nuts and bolts—better maintenance, skilled operators, and smart automation.

Real world change comes slow, but each small step adds up. By choosing safer catalysts and building smarter plants, companies can keep jobs in town and shrink the environmental drag. Cumene touches more corners of our lives than most people realize, giving its production an outsized impact on both our economy and environment.

Cumene, sometimes called isopropylbenzene, finds its way into many chemical processes, mostly as a starting material for making phenol and acetone. Anyone who’s dealt with industrial chemicals knows even things that seem simple carry their risks. Cumene gives off flammable vapors, carries a distinct, gasoline-like odor, and has a knack for forming explosive air-vapor mixtures at surprisingly low temperatures. That calls for respect in handling.

Experience with organic solvents teaches the importance of designated storage. Flammable liquids like cumene belong in a cool, well-ventilated facility away from direct sunlight and heat sources. Steel drums or dedicated storage tanks do the job, provided they stay tightly closed and checked for leaks. Storage areas for cumene should not sit next to open flames, static-producing equipment, or oxidizers like chlorine or nitric acid, since even one oversight can turn a routine day into an emergency. Fire-resistant construction and properly placed spill containment barriers offer practical safeguards.

Flammable liquid cabinets stand out as ideal small-scale storage solutions. Grounding both containers and tanks before handling helps avoid static—the silent troublemaker in many solvent accidents.

Anyone working with cumene in the real world, not just theory, knows accidents don’t ask permission. Proper personal protective equipment makes all the difference: chemical goggles to guard against eye exposure, gloves made for organic chemicals, flame-resistant lab coats or coveralls, and shoes that won’t let chemicals seep through. Showing new team members how to transfer cumene safely matters just as much as reading the safety data sheet. Pouring from one drum to another calls for closed systems or pumps with vapor-tight seals. Pouring liquids in open air lets vapors escape and keeps everyone guessing about their exposure. Good local exhaust ventilation whisks vapors away, protecting people at the front lines.

Fire drills that include simulated solvent spills sound tedious until real trouble hits. Fast action depends on confidence, not panic. Every storage room should have dry chemical or foam extinguishers ready—water just spreads most organic chemical fires. Where there’s risk, there should be spill-control kits: absorbent pads for small leaks, drain covers to prevent chemicals from reaching the sewer, and simple tools like non-sparking scoops and buckets.

Clean-up teams should know the evacuation plan just as well as they know how to seal a leaking drum. Workers need to report symptoms like dizziness or throat irritation, since repeated exposure to cumene vapors can cause headaches or harm the liver and kidneys over time. No job is worth risking long-term health.

Consistent training, regular checks of equipment, and honest communication between workers and safety officers build trust. Clear, simple labeling on every drum, and making safety data sheets accessible, push everyone to act responsibly. I’ve seen workplaces where leaders model safe behavior, and people stop each other before mistakes happen. That’s how you avoid both surprises and complacency. With careful handling and a little respect for what cumene can do, most problems can be stopped before they ever start.

| Names | |

| Preferred IUPAC name | isopropylbenzene |

| Other names |

Isopropylbenzene 2-Phenylpropane Cumol Cumolene Isopropylbenzol |

| Pronunciation | /ˈkjuːmiːn/ |

| Identifiers | |

| CAS Number | 98-82-8 |

| Beilstein Reference | 635374 |

| ChEBI | CHEBI:28272 |

| ChEMBL | CHEMBL14124 |

| ChemSpider | 5756 |

| DrugBank | DB03627 |

| ECHA InfoCard | 100.003.786 |

| EC Number | EC 202-704-5 |

| Gmelin Reference | 915 |

| KEGG | C01407 |

| MeSH | D003437 |

| PubChem CID | 6618 |

| RTECS number | GY1400000 |

| UNII | F5AE5P7EPV |

| UN number | UN1918 |

| Properties | |

| Chemical formula | C9H12 |

| Molar mass | 120.19 g/mol |

| Appearance | Colorless liquid |

| Odor | Aromatic |

| Density | 0.862 g/cm³ |

| Solubility in water | Negligible |

| log P | 3.66 |

| Vapor pressure | 4 mmHg (20°C) |

| Acidity (pKa) | 41.1 |

| Basicity (pKb) | 10 |

| Magnetic susceptibility (χ) | -8.31×10⁻⁶ |

| Refractive index (nD) | 1.491 |

| Viscosity | 0.664 cP at 25°C |

| Dipole moment | 4.63 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 197.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -20.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3339.7 kJ/mol |

| Pharmacology | |

| ATC code | J61AX25 |

| Hazards | |

| GHS labelling | GHS02, GHS07, GHS08 |

| Pictograms | Flame, Exclamation mark, Health hazard, Environment |

| Signal word | Danger |

| Hazard statements | H226, H304, H315, H319, H335, H411 |

| Precautionary statements | P210, P260, P273, P301+P310, P303+P361+P353, P304+P340, P331, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | 43°C |

| Autoignition temperature | 464 °C |

| Explosive limits | 1.1–6.5% |

| Lethal dose or concentration | LD50 (oral, rat): 1400 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Cumene: **1400 mg/kg (oral, rat)** |

| NIOSH | CU1400000 |

| PEL (Permissible) | 50 ppm |

| REL (Recommended) | 50 ppm |

| IDLH (Immediate danger) | 900 ppm |

| Related compounds | |

| Related compounds |

Benzene Isopropyl alcohol Phenol Acetone Styrene |